We claim :

1. A process for removing metal from an aqueous medium containing in solution one or more metals selected from the group consisting of opatinum, rhodium, palladium, ruthenium, gold, silver, iridium, zinc, aluminum, iron, copper, nickel and tin which comprises contacting said aqueous medium with at least one unmodified proteinaceous material selected from the group consisting of feathers, hair, hoof meal and horn meal of time sufficient to convert metal in solution to water insoluble form in association with said proteinaceous material, and separating loaded proteinaceous material containing removed metal from the resulting treated aqueous medium.

2. The process of claim 1 wherein metal values are recovered from said loaded proteinaceous material.

3. The process of claim 1 wherein the aqueous medium contains at least one of the metals platinum, palladium and rhodium, in solution.

4. A process according to claim 1 wherein said proteinaceous material is maintained in contact with said aqueous medium for a period of at least one hour.

5. A process according to claim 3 wherein said contacting step is carried out at a temperature in the range of 5℃ to 90℃.

6. A process according to claim 1 wherein said proteinaceous material is contacted with successive amounts of fresh aqueous medium.

7. A process according to claim 6 wherein successive amounts of fresh proteinaceous material are contacted with previously contacted aqueous medium.

8. A process according to claim 7 wherein proteinaceous material which has been subjected to contact with successive amounts of fresh aqueous medium is withdrawn from said process and tread for the recovery of metal values therefrom.

9. A process according to claim 8 wherein a series of batches of proteinaceous material are contacted with said aqueous medium in suecession, the solution contacting first the batch of proteinaceous material which has previously been contacted with the greatest amount of aqueous medium and finally contacting the batch of proteinaceous material which has previously been contacted with the least amount of aqueous medium.

10. A process according to claim 1 wherein said aqueous medium is introduced into an elongated contacting zone at a point adjacent one end and said proteinaceous material is introduced at a point adjacent the other end of said zone wherein said aqueous medium and said proteinaceous material move in said zone in opposite directions and in intimate countercurrent contact with one another treated aqueous medium is removed from said zone adjacent the point of introduction of said proteinaceous material and loaded proteinaceous material is removed from said zone adjacent the point of introduction of said aqueous medium.

11. A process according to claim 9 or claim 10 wherein said aqueous medium contains at least one of the metals platinum, palladium and rhodium, in solution.

参考译文

实施例1-3

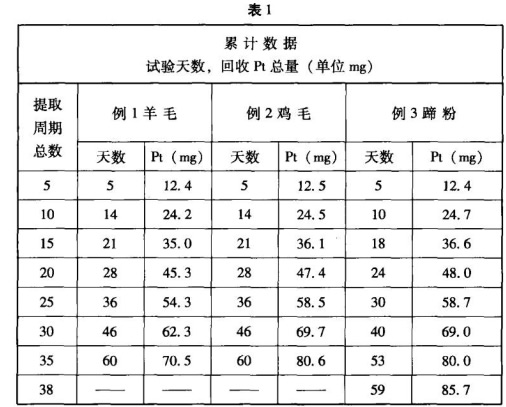

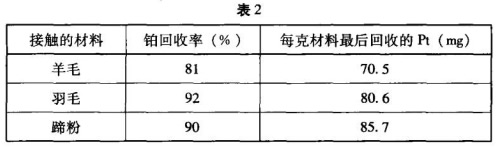

取蹄粉、织锦白羊毛、原生鸡毛各一克,分别放在三个盛有25毫升100ppm氯钼酸溶液的离心管中,然后将离心管放置在往复式振动机上,试验时温度为28℃。最初试验周期为一天,在每个周期末,把管子中的溶液换成新的溶液。如表1所示,在几个周期之后,周期的时间增至两天以上。对离心出来的固体,采 用氯化亚锡比色分析法测微量的铂定。在38周期末,蹄粉已经把溶液中90%的铂回收。每克蹄粉回收85. 7毫克铂。在35周期末,羊毛已回收81%的铂。每克羊毛回收钴70. 5毫克。在35 周期,羽毛已回收92%的铂,每克羽毛回收80. 6毫克铂。试验结果在表2中示出。

上一篇:俄语章节之间顾望后文,提前交代

下一篇:化学专利说明书翻译示例a

微信公众号搜索“译员”关注我们,每天为您推送翻译理论和技巧,外语学习及翻译招聘信息。